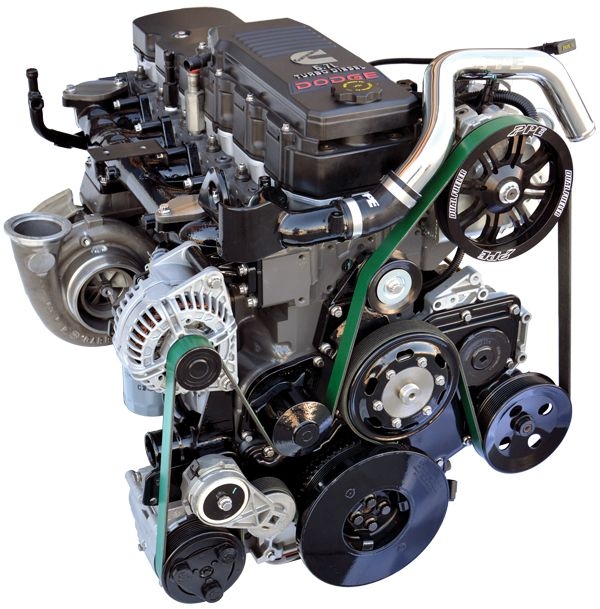

The PPE Dual Fueler Kit is great for highly modified engines that produce up to 2000 hp and 26,000+ psi! Xcelerator, the fuel pressure can be increased over factory pressure resulting in additional horsepower and torque gains. If the tuning is modified such as with an Xcelerator or a Hot+2 E.T. The Dual Fueler Kit will not produce more fuel pressure than the ECU requests it will only increase fuel volume. In the event of pump failure, PPE's electronic controller will automatically switch all fuel delivery responsibilities to the remaining operational pump. Both pumps work together, each delivering half the total volume of fuel required. Adding our kit to your stock fuel system reduces drive load on the stock CP3 pump, thereby increasing pump reliability.

meet European emission standards - Ⅲ, without exhaust post-treatment.Our PPE belt-driven Bosch CP3 fuel pump works in conjunction with the stock fuel system and is controlled by a sophisticated microprocessor module.Low maintenance costs - the rear chain drive of a lifetime maintenance-free pressure plate quilting grinding process so that the piston rings and cylinder bore a perfect match to reduce oil consumption and delay the aging of oil, increasing oil replacement cycle 20,000 km long oil cycle maintenance cost per kilometer is only 1/3 of the similar models Low fuel costs - for the specific use conditions of the vehicle matching optimization, greatly reducing vehicle fuel economy Low maintenance costs - modular design greatly reduces the number of parts, so that the point of failure, the failure surface to a minimum Use low cost - in order to bring the best comprehensive and effectiveness.The whole design of reserve oil heating and coolant heating options, to meet the minus 40 degrees starting. Bosch common rail system and the Cummins electronically controlled cold start control strategy greatly improve the starting performance Optional hood cover to further reduce the overall noise Crankshaft driven oil pump rotor and chain drive design are effective to ensure the overall low-noise Home sprocket chamber design than similar front gear room models to reduce the noise of 1 dB noise, low vibration - one of the quietest diesel engine.B10 life of 500,000 kilometers of similar models, more than twice. In a fully enclosed air-conditioned workshop robot assembly to control the torque of all bolts and other control requirements

Five critical systems highly integrated to achieve integrated control electronics module by the ECM, to achieve the best performance The engine structure to strengthen: integral cylinder block, cylinder head, higher strength, greater stability International supplier of high-quality supply of the main components, the harmonization of procurement by the Cummins global supply chain, to ensure the quality of the parts high reliability and -50 million km without major repairs to two times the average for similar models.

Cummins combustion technologies, and electronic control technology combined with high pressure common rail fuel system applications leading to greatly reduced fuel consumption. 4 valves per cylinder design to improve intake efficiency and reduce fuel consumption Cylinder head cover and oil pan using synthetic materials to reduce the weight of the whole in order to reduce fuel consumption

0 kommentar(er)

0 kommentar(er)